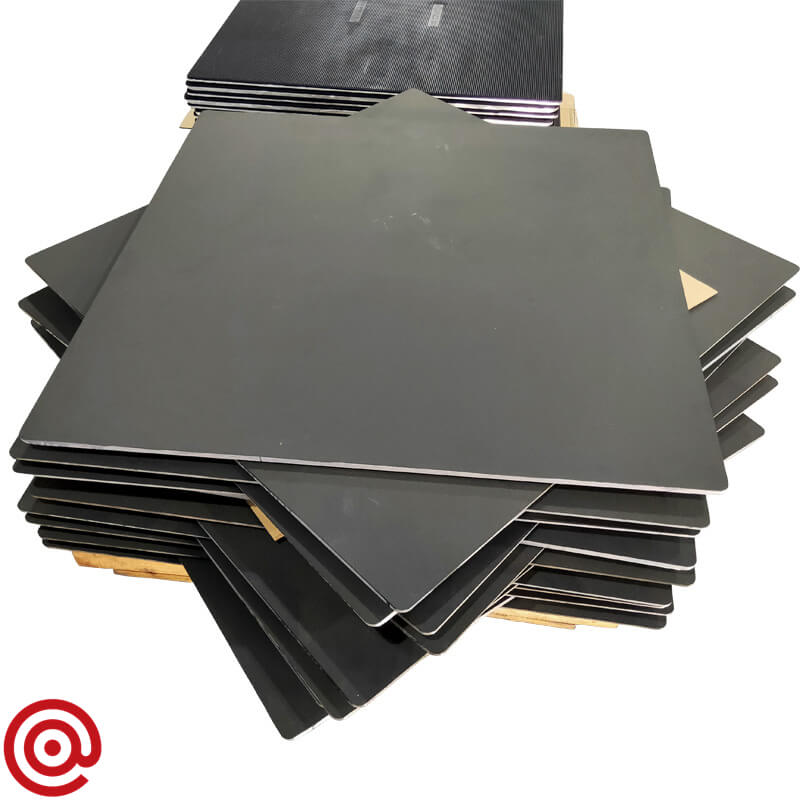

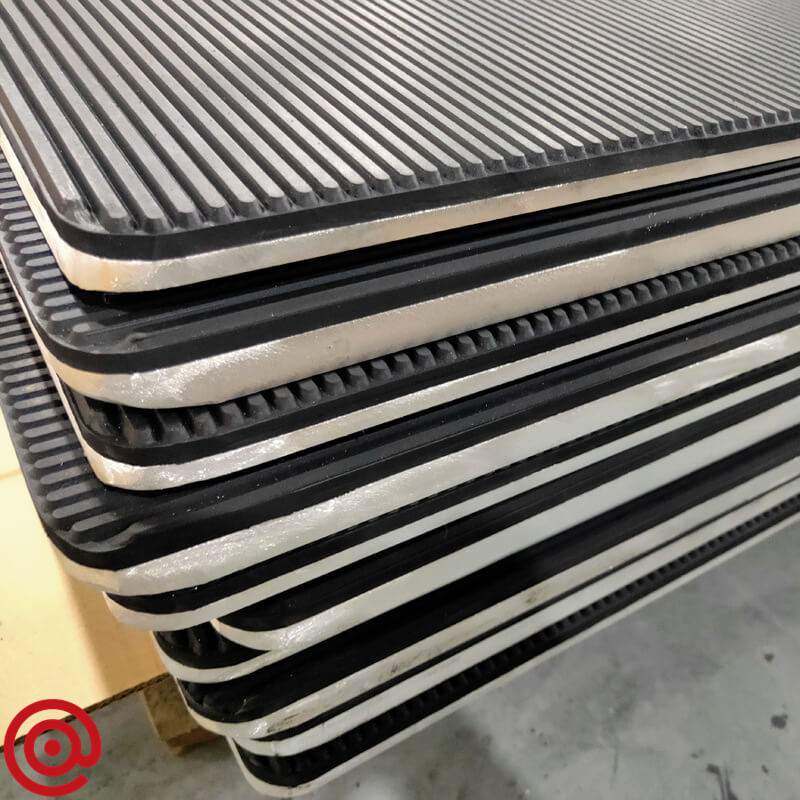

Forklift Black Aluminum Alloy Clamping Rubber Plate

Rubber forklift attachments are essential components that play a crucial role in enhancing the functionality and safety of forklift operations. These rubber parts are specifically designed to improve grip, reduce noise, protect delicate materials, and enhance stability during material handling tasks. With their versatile applications and durable construction, rubber forklift attachments are widely used in various industries such as warehousing, logistics, manufacturing, and construction.

One of the most common rubber parts used in forklift attachments is the rubber tire. These tires are made from high-quality rubber compounds that provide excellent traction and grip on different surfaces. The specialized tread patterns on the tires help to enhance stability and maneuverability, allowing the forklift to navigate smoothly even on uneven terrain or slippery floors. Rubber tires also absorb shocks and vibrations, reducing operator fatigue and protecting fragile loads from damage.

Another important rubber part is the load wheel, which is typically attached to the forklift’s mast. Load wheels are designed to carry heavy loads and distribute the weight evenly, minimizing the risk of tip-overs. These rubber wheels are engineered with a combination of hardness and flexibility to ensure optimal performance and longevity. They are resistant to wear and tear, allowing for prolonged and efficient operation in demanding environments.

Rubber bumpers and protective covers are additional rubber parts used in forklift attachments. These components are strategically placed on the forklift’s frame and forks to prevent damage during material handling operations. Rubber bumpers act as shock absorbers, reducing impact forces when the forklift comes into contact with racks, walls, or other objects. They help to prevent costly repairs and extend the lifespan of the forklift. Protective covers, on the other hand, shield delicate loads from scratches, abrasions, and impact damage caused by the forklift’s metal forks.

Furthermore, rubber pads and mats are commonly used as attachments on forklift forks. These pads provide a non-slip surface, improving grip and stability when lifting and transporting goods. They also act as a cushion, reducing the risk of product damage by absorbing vibrations and preventing slippage. Rubber pads and mats are available in various sizes and thicknesses to accommodate different load types and weights.

In summary, rubber forklift attachments comprise a range of essential rubber parts that enhance the performance, safety, and efficiency of forklift operations. From tires and load wheels to bumpers, covers, pads, and mats, these rubber components provide superior grip, protection, and stability. With their durable construction and versatile applications, rubber forklift attachments are indispensable tools in the material handling industry, enabling operators to handle loads with confidence and precision.

- Material:EPDM NBR Silicon or Can Custom

- Logo:Can Custom

- Size:Can Custom

- Can Custom:Black or custom

- Certifications:IATF16949, ISO14001:2015, ROHS, CMC, etc

- Delivery:30 -50days after sample confirmation

- Sample:25-30 days

- Payment:30% deposit, 70% payment before shipment

- Package:PE bags, Cartons, Pallet

- Payment Terms:T/T, L/C and so forth.

- Shipment Way:Vessel, Air, Express etc.